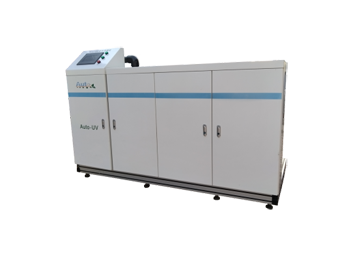

The automatic ultraviolet disinfection machine is used to disinfect the wastewater generated by the nutrient solution recovery system. The system uses ultraviolet and filtration technology to eliminate 90% of crop harmful substances in the return liquid, ensuring that the nutrient solution is safe and reusable.

Technical parameters:

1. Ultraviolet lamp: 800W, life span is 12,000 hours

2. Capacity: Model I: 4m³/H, Model 2: 8m³/H

3. Automatic acid cleaning of UV lamp: To ensure that the UV lamp maintains 100% clarity, the system is equipped with "ultraviolet radiation intensity sensor" and "nutrient solution pH sensor", and is designed with the function of automatically cleaning the UV lamp with acid. At the same time, the system is equipped with a 100L "acid storage tank".

4. The system is equipped with "unsterilized liquid level sensor" and "sterilized liquid level sensor". When the unsterilized liquid level is higher than the set value, the disinfection can be automatically started. When the unsterilized liquid level is lower than the set stop value or the sterilized liquid level is higher than the set stop value, the disinfection is forced to stop.

5. The system is designed with a UV lamp preheating function. When the UV lamp is preheated, the UV radiation intensity of the UV lamp gradually increases. At this time, the system will automatically guide the unsterilized liquid back to the unsterilized liquid storage tank.

6. The system is designed with an ultrasonic flow sensor and a water pump constant pressure variable frequency speed regulation system to adjust the flow rate of the liquid in the UV lamp.

7. Color touch screen operation: The system is designed with a 10-inch color touch screen for interactive operation of the disinfection machine on the device.

8. Remote cloud control and mobile phone operation: The system can remotely operate the disinfection machine from any location through a PC via the Internet, and can also remotely operate the disinfection machine on the mobile phone.